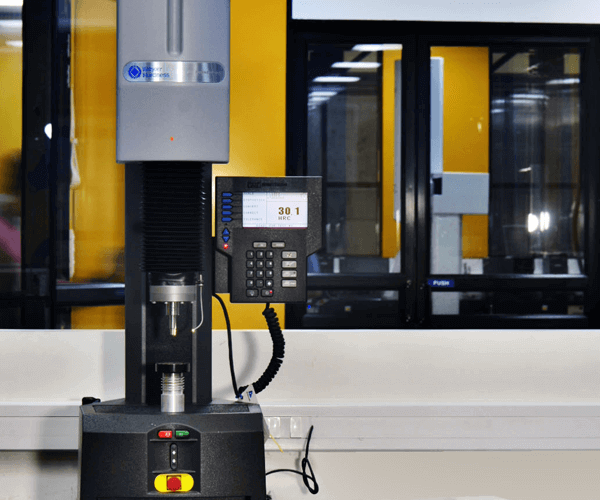

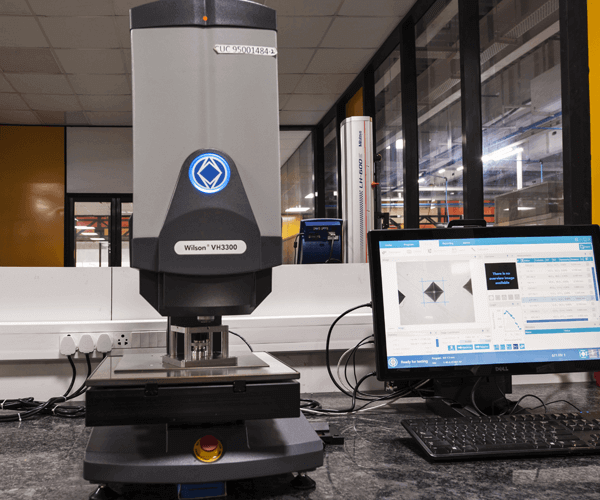

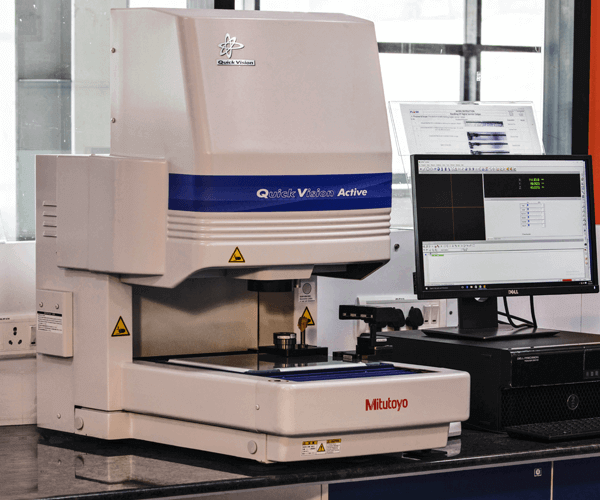

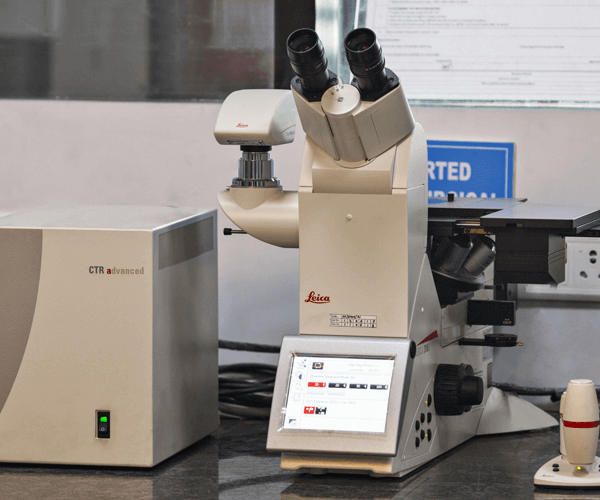

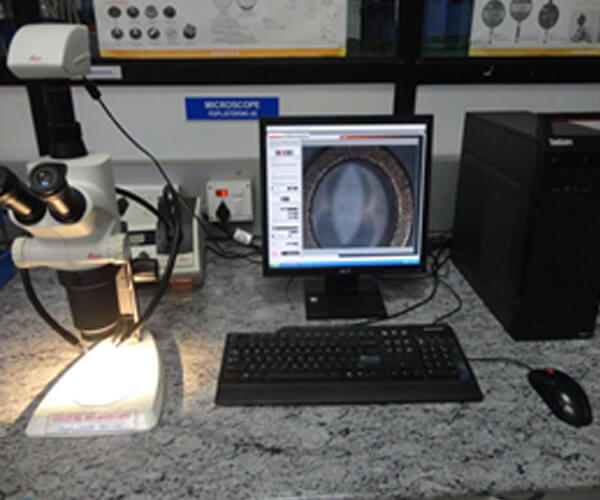

Some of our Quality Testing Equipment Include:

Breakdown Tester

Elongation Tester

Microscope Digital Display

Cut Through Tester

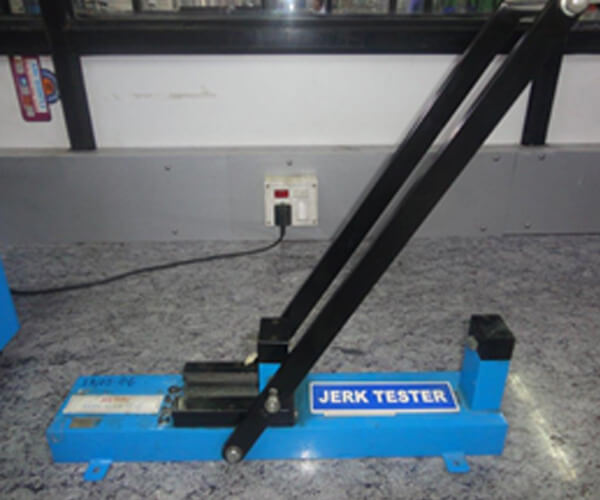

Jerk Tester

Insulation Peel Off Tester

Service beyond expectations, products as per exact design specifications, at optimal cost is our motto at Flash when it comes to Quality

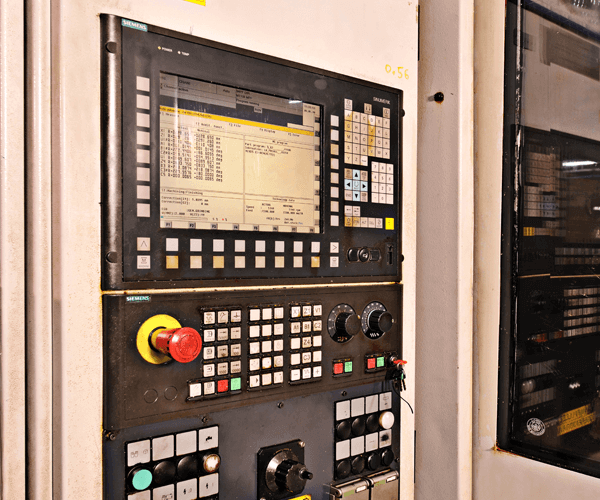

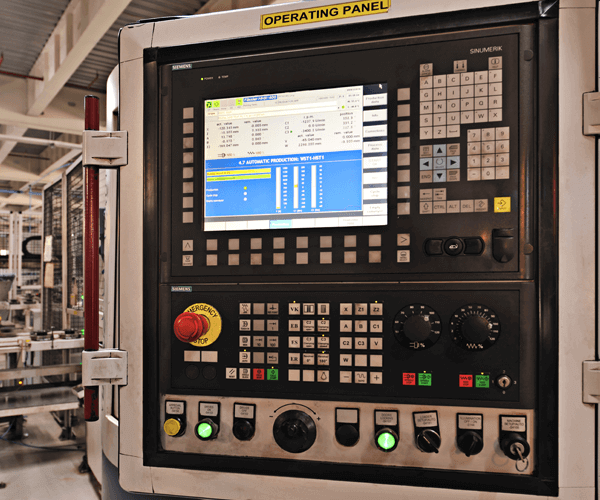

Our Primary responsibility is to deliver maximum value to our customers. In pursuance of this effort, with our dedicated team of professionals, we commit ourselves to maintain the leadership both in quality and technology of our products through our in house quality assurance systems.

Being a TPM driven company, we stand committed towards elimination of defects and losses.

We at Flash are committed to work towards a greener and cleaner environment and safeguard the health and safety of all personnel associated with the environment.

Flash has attained the status of Preferred Auto Electrical/ Electronics full system solution provider by consistently monitoring quality of components supplied, increasing quantity during ramp ups and delivering innovative products cost effectively within the stipulated time frame.

Service beyond expectation, products as per exact specification, at optimal costs is the mantra when it comes to our approach towards quality.

IATF 16949

ISO 14001

OHSAS 18001

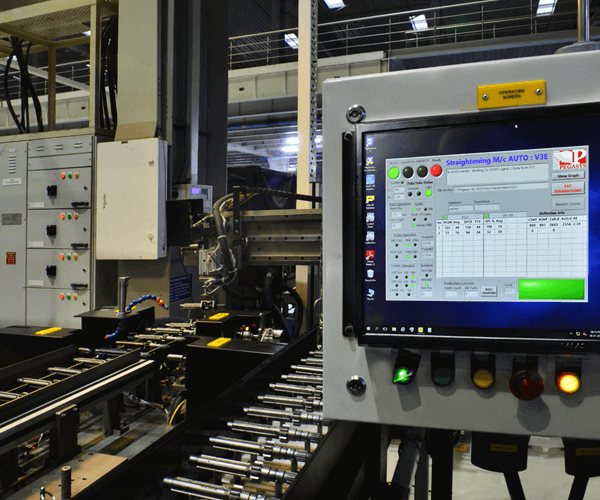

We follow all pre-requisite industry norms to ensure products are made as per specification and deliver on their functionality far beyond minimum expectations. Some of the quality centric processes followed include regular checks of precision measurement instruments and equipment, well displayed Kanban boards, Kaisen implementation and Poke Yoke stations.