R&D Capabilities

Research & Development

FLASH was amongst the First Indian SMEs (Small & Medium Enterprises) in Automotive Electricals & Electronics Component Category to be conferred with the prestigious “R&D House Recognition” from the Ministry of Science and Technology - Government of India on February 28, 2008.

We have a 4 step watertight R&D process. At step 1, we create design concepts based on customer requirements and briefs. Here simulations are used for feasibility analysis and design freeze.

After concept approvals, comes step 2 and 3 of product design and its optimization, wherein an in house experienced team of engineers specializing in multiple areas viz., Mechanics, Electrical, Electronic Components and Magnetism work on the concepts to create MVPs. Exceptional designing is an integral aspect of all Flash products. We have an in-house team of highly-trained product engineering designers having expertise in latest design softwares. Their extensive experience in designing of components, tools and assembly lines is critical to our efficient designs and engineering costs.

The final and crucial step of the process is the Validation Testing to ascertain expected design performance. Every product at Flash Electronics undergoes a series of validation tests in our in-house Endurance Laboratory. Quick validation for approving new designs and early implementation of VAVE Ideas is seamlessly executed in this lab.

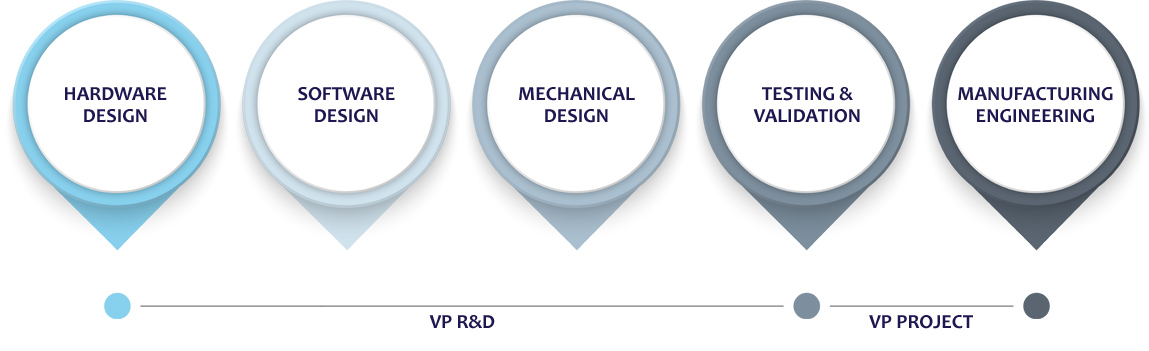

Engineering Activities - Managed by 4 groups + Supported by Manufacturing Engineering Group